Ultrasonic Cleaning

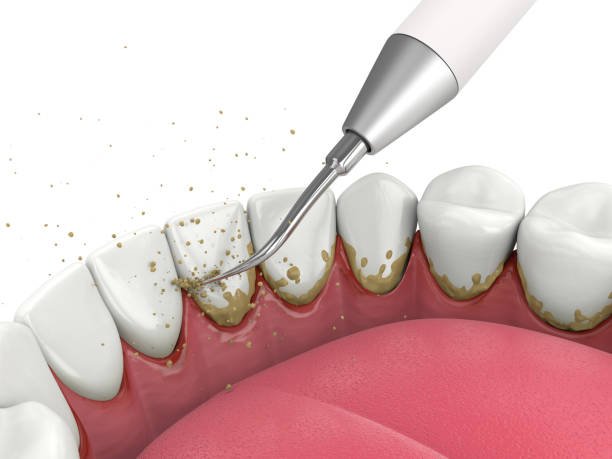

Ultrasonic cleaning is a highly effective and widely used technology in various industries for the meticulous cleaning of objects and surfaces. It employs ultrasonic waves, which are sound waves with frequencies higher than the upper audible limit of human hearing, typically above 20,000 hertz. This innovative cleaning method relies on the creation of microscopic bubbles through a process known as cavitation, leading to efficient removal of contaminants.

Ultrasonic cleaning is a highly effective and widely used technology in various industries for the meticulous cleaning of objects and surfaces. It employs ultrasonic waves, which are sound waves with frequencies higher than the upper audible limit of human hearing, typically above 20,000 hertz. This innovative cleaning method relies on the creation of microscopic bubbles through a process known as cavitation, leading to efficient removal of contaminants.

Key Aspects of Ultrasonic Cleaning:

Cavitation Process:

Ultrasonic cleaning relies on the phenomenon of cavitation, where high-frequency sound waves generate tiny bubbles in a liquid medium. These bubbles rapidly expand and collapse, creating shock waves that dislodge and remove dirt, debris, and contaminants from surfaces.

Cleaning Solution:

A specialized cleaning solution is used in the ultrasonic cleaning process. The cleaning solution enhances the cavitation effect and facilitates the removal of contaminants from the objects being cleaned.

Applications:

Ultrasonic cleaning finds applications in diverse industries, including healthcare (cleaning medical instruments), automotive (cleaning engine parts), electronics (cleaning circuit boards), jewelry manufacturing, and even in the restoration of delicate historical artifacts.

Precision Cleaning:

The microscopic nature of cavitation bubbles allows ultrasonic cleaning to reach intricate and hard-to-reach areas that may be challenging for other cleaning methods. This makes it particularly useful for cleaning complex and delicate objects.

Gentle on Materials:

Ultrasonic cleaning is generally gentle on materials. While highly effective in removing contaminants, it typically doesn’t cause damage to the objects being cleaned, making it suitable for delicate items.

Automated Systems:

Ultrasonic cleaning systems can be designed as automated units, allowing for efficient and consistent cleaning processes. This is especially beneficial in industrial settings where large quantities of items need to be cleaned.

Environmental Considerations:

Ultrasonic cleaning is often considered environmentally friendly as it reduces the need for harsh chemical cleaning agents. The process itself relies on the physical action of cavitation rather than chemical reactions.

Versatility:

The versatility of ultrasonic cleaning makes it suitable for various materials, including metals, plastics, glass, ceramics, and more. It is employed in both industrial settings and smaller-scale applications.

Maintenance of Equipment:

Regular maintenance of ultrasonic cleaning equipment is essential to ensure optimal performance. This includes checking transducers, power supplies, and ensuring that the cleaning solution is appropriate for the specific application.

Quality Assurance:

Ultrasonic cleaning is known for its role in quality assurance, especially in industries where cleanliness and precision are critical, such as in medical and aerospace manufacturing.

In summary, ultrasonic cleaning is a powerful and versatile technology that has revolutionized the cleaning processes across various industries. Its ability to provide thorough and precise cleaning, coupled with its adaptability to different materials and applications, makes it a valuable tool for maintaining the cleanliness and integrity of a wide range of objects and surfaces.